OEM tools provide in-depth diagnostic support for vehicles equipped with thermoelectric climate seats (heating/cooling) by accessing specific modules like the SCME, reading DTCs, and enabling component-level testing. CAR-SCAN-TOOL.EDU.VN offers specialized training to help technicians master these tools, ensuring accurate diagnoses and efficient repairs. This training focuses on advanced diagnostic techniques, data interpretation, and remote support, empowering technicians to excel in automotive diagnostics.

Contents

- 1. What are Thermoelectric Climate Seats and Why Do They Require Specialized Diagnostics?

- 1.1 Understanding the Components of Thermoelectric Climate Seats

- 1.2 Why Standard Diagnostic Tools May Fall Short

- 2. How Do OEM Diagnostic Tools Enhance Thermoelectric Climate Seat Diagnostics?

- 2.1 Direct Access to the Seat Climate Control Module (SCME)

- 2.2 Reading and Interpreting Diagnostic Trouble Codes (DTCs)

- 2.3 Live Data Monitoring and Analysis

- 2.4 Actuator Testing for Component Verification

- 2.5 Recalibration and Reprogramming of the SCME

- 3. OEM Tool Procedures for Diagnosing Thermoelectric Climate Seat Issues

- 4. Case Studies: How OEM Tools Resolved Complex Climate Seat Issues

- 4.1 Case Study 1: Intermittent Heating/Cooling Failure

- 4.2 Case Study 2: Overheating Issue

- 4.3 Case Study 3: Blower Motor Malfunction

- 5. The Importance of Training in Utilizing OEM Diagnostic Tools

- 5.1 Benefits of Training with CAR-SCAN-TOOL.EDU.VN

- 5.2 Course Offerings Related to Diagnostic Tools and Climate Seat Systems

- 5.3 Remote Technician Education and Support

- 6. Common Mistakes to Avoid When Diagnosing Thermoelectric Climate Seats

- 6.1 Neglecting DTC Analysis

- 6.2 Ignoring Live Data

- 6.3 Skipping Actuator Tests

- 6.4 Overlooking Basic Checks

- 6.5 Failing to Verify Repairs

- 7. Future Trends in Thermoelectric Climate Seat Diagnostics

- 7.1 Enhanced Diagnostic Capabilities

- 7.2 Integration with Cloud-Based Platforms

- 7.3 Augmented Reality (AR) Applications

- 8. Key Takeaways for Effective Climate Seat Diagnostics

- 9. How CAR-SCAN-TOOL.EDU.VN Prepares Technicians for the Future of Automotive Diagnostics

- 10. Frequently Asked Questions (FAQs) About Thermoelectric Climate Seat Diagnostics

- 10.1 What is a thermoelectric climate seat?

- 10.2 Why do thermoelectric climate seats require specialized diagnostic tools?

- 10.3 What are the key components of a thermoelectric climate seat system?

- 10.4 What is the SCME and what does it do?

- 10.5 What types of diagnostic trouble codes (DTCs) are common in thermoelectric climate seat systems?

- 10.6 How can live data monitoring help diagnose climate seat issues?

- 10.7 What are actuator tests and how are they used in climate seat diagnostics?

- 10.8 Can the SCME be recalibrated or reprogrammed?

- 10.9 What are some common mistakes to avoid when diagnosing thermoelectric climate seats?

- 10.10 How can CAR-SCAN-TOOL.EDU.VN help technicians improve their climate seat diagnostic skills?

- 11. Conclusion: Mastering Thermoelectric Climate Seat Diagnostics with the Right Tools and Training

1. What are Thermoelectric Climate Seats and Why Do They Require Specialized Diagnostics?

Thermoelectric climate seats, also known as heated and cooled seats, use a thermoelectric device (TED) to either heat or cool the seat. Unlike traditional heated seats that only provide warmth, these systems offer both heating and cooling, enhancing comfort in various weather conditions. These advanced systems require specialized diagnostics due to their complexity, involving multiple sensors, blower motors, and a dedicated control module.

1.1 Understanding the Components of Thermoelectric Climate Seats

Thermoelectric climate seats typically consist of the following components:

- Blower Motors: Circulate air through the seat.

- Thermoelectric Device (TED): Heats or cools the air.

- Temperature Sensors: Monitor seat temperature to regulate heating/cooling.

- Seat Climate Control Module (SCME): Controls the system based on user settings and sensor data.

- Control Interface: Allows the user to adjust the heating and cooling levels.

1.2 Why Standard Diagnostic Tools May Fall Short

While standard OBD-II scanners can read generic trouble codes, they often lack the ability to access the specific data and perform the necessary tests to diagnose issues within the thermoelectric climate seat system. OEM tools and advanced scan tools offer deeper access, enabling technicians to:

- Read module-specific diagnostic trouble codes (DTCs).

- Access live data from temperature sensors and blower motors.

- Perform component-level testing.

- Recalibrate or reprogram the SCME.

2. How Do OEM Diagnostic Tools Enhance Thermoelectric Climate Seat Diagnostics?

OEM (Original Equipment Manufacturer) diagnostic tools are designed specifically for vehicles from a particular manufacturer. These tools offer unparalleled access to vehicle systems, making them invaluable for diagnosing complex issues like those found in thermoelectric climate seats.

2.1 Direct Access to the Seat Climate Control Module (SCME)

OEM tools allow technicians to directly communicate with the SCME, which is responsible for controlling the heating and cooling functions of the seats. This direct access enables technicians to:

- Read and clear DTCs: Identify specific issues within the system.

- View live data: Monitor temperature sensors, blower motor speeds, and TED operation in real-time.

- Perform actuator tests: Activate individual components to verify their functionality.

- Reprogram the SCME: Update the module’s software to address known issues or improve performance.

2.2 Reading and Interpreting Diagnostic Trouble Codes (DTCs)

OEM tools provide detailed descriptions of DTCs related to the thermoelectric climate seat system, helping technicians pinpoint the exact location and nature of the problem. Common DTCs may include:

- B2729/B2730: Overtemperature faults.

- B272A/B272B: Temperature difference faults between the seat cushion and backrest.

- Communication errors: Indicate issues with the SCME’s ability to communicate with other modules.

- Component failure codes: Suggest problems with specific components like blower motors or temperature sensors.

2.3 Live Data Monitoring and Analysis

Live data monitoring allows technicians to observe the system’s performance in real-time. OEM tools display crucial data points, such as:

- Seat cushion temperature.

- Backrest temperature.

- Blower motor speed (RPM).

- Thermoelectric Device (TED) voltage/current.

- Ambient air temperature.

By analyzing this data, technicians can identify anomalies that may indicate a problem. For example, a temperature sensor reading significantly higher or lower than expected could indicate a faulty sensor or a problem with the TED.

2.4 Actuator Testing for Component Verification

Actuator tests enable technicians to directly control individual components of the thermoelectric climate seat system. This feature helps verify the functionality of each component. Examples of actuator tests include:

- Blower motor activation: Tests the blower motor’s ability to run at different speeds.

- TED activation: Tests the TED’s ability to heat and cool.

- Temperature sensor simulation: Tests the SCME’s response to different temperature readings.

2.5 Recalibration and Reprogramming of the SCME

In some cases, issues with thermoelectric climate seats can be resolved through recalibration or reprogramming of the SCME. OEM tools provide the necessary software and procedures to perform these tasks. Recalibration may be needed after replacing components or to address minor software glitches. Reprogramming involves updating the SCME’s software to the latest version, which may include bug fixes and performance improvements.

3. OEM Tool Procedures for Diagnosing Thermoelectric Climate Seat Issues

Diagnosing issues with thermoelectric climate seats using OEM tools typically involves a systematic approach:

- Initial Scan: Perform a full system scan to identify any DTCs related to the climate seat system.

- DTC Analysis: Research the DTCs to understand the potential causes and affected components.

- Live Data Monitoring: Monitor relevant data points while operating the climate seats to identify any anomalies.

- Actuator Tests: Perform actuator tests to verify the functionality of individual components.

- Component Inspection: Physically inspect the components, including wiring, connectors, and the SCME, for any signs of damage or corrosion.

- Recalibration/Reprogramming: If necessary, perform recalibration or reprogramming of the SCME using the OEM tool.

- Verification: After making repairs, clear the DTCs and retest the system to ensure the issue has been resolved.

4. Case Studies: How OEM Tools Resolved Complex Climate Seat Issues

Here are a few examples of how OEM tools have been used to diagnose and resolve complex issues with thermoelectric climate seats:

4.1 Case Study 1: Intermittent Heating/Cooling Failure

Vehicle: 2018 Ford Explorer

Problem: The driver’s side climate seat would intermittently stop heating or cooling. No DTCs were present.

Diagnosis: Using the Ford OEM diagnostic tool, the technician monitored live data from the temperature sensors. The data revealed that the temperature sensor on the seat cushion was occasionally dropping to zero, causing the SCME to shut down the system.

Solution: The technician replaced the faulty temperature sensor. After clearing the memory and verifying the system with the OEM tool, the seat operated normally.

4.2 Case Study 2: Overheating Issue

Vehicle: 2020 Cadillac Escalade

Problem: The passenger’s side climate seat was overheating, even on the lowest setting.

Diagnosis: The technician used the GM OEM diagnostic tool to read DTCs. The diagnostic scanner identified a B2729 code indicating an overtemperature fault. Live data monitoring showed that the TED was not regulating temperature correctly.

Solution: The technician replaced the TED, reprogrammed the SCME with the latest software, and verified proper operation using the GM OEM tool.

4.3 Case Study 3: Blower Motor Malfunction

Vehicle: 2017 Lincoln MKZ

Problem: The blower motor in the driver’s seat was not functioning.

Diagnosis: Using the Lincoln OEM diagnostic tool, the technician performed an actuator test on the blower motor. The test confirmed that the motor was not responding. Further inspection revealed a faulty blower motor relay.

Solution: The technician replaced the blower motor relay and verified proper operation using the Lincoln OEM tool.

5. The Importance of Training in Utilizing OEM Diagnostic Tools

While OEM tools offer advanced capabilities, their effective use requires specialized training. Technicians need to understand:

- The specific functions and features of the OEM tool.

- The operation of thermoelectric climate seat systems.

- How to interpret DTCs and live data.

- Proper diagnostic procedures.

- Recalibration and programming procedures.

CAR-SCAN-TOOL.EDU.VN offers comprehensive training programs designed to equip technicians with the skills and knowledge needed to effectively use OEM diagnostic tools and diagnose complex automotive systems.

5.1 Benefits of Training with CAR-SCAN-TOOL.EDU.VN

- Expert Instructors: Learn from experienced automotive technicians with in-depth knowledge of OEM diagnostic tools and climate control systems.

- Hands-On Training: Gain practical experience using OEM tools on real vehicles.

- Comprehensive Curriculum: Cover all aspects of climate seat diagnostics, from basic principles to advanced troubleshooting techniques.

- Flexible Learning Options: Choose from online and in-person training programs to fit your schedule and learning style.

- Certification: Earn a certification upon completion of the program to demonstrate your expertise.

5.2 Course Offerings Related to Diagnostic Tools and Climate Seat Systems

CAR-SCAN-TOOL.EDU.VN offers a range of courses that can benefit technicians working with thermoelectric climate seat systems:

| Course Name | Description | Target Audience |

|---|---|---|

| OEM Diagnostic Tool Mastery | A comprehensive course covering the use of OEM diagnostic tools for various vehicle systems. | Technicians seeking to enhance their diagnostic skills |

| Advanced Climate Control Diagnostics | Focuses specifically on diagnosing issues with advanced climate control systems, including thermoelectric climate seats. | Technicians specializing in climate control systems |

| Electrical System Troubleshooting | Provides in-depth knowledge of electrical system diagnostics, essential for understanding the wiring and control systems of climate seats. | Technicians looking to improve electrical diagnostics |

| Data Analysis for Automotive Diagnostics | Teaches technicians how to interpret and analyze live data from vehicle sensors, crucial for identifying issues with climate seats and other systems. | Technicians aiming to master data-driven diagnostics |

5.3 Remote Technician Education and Support

CAR-SCAN-TOOL.EDU.VN recognizes the importance of accessible and flexible education. Our remote technician education programs bring expert-led training directly to you, regardless of your location. Through interactive online courses, virtual labs, and remote support, you can gain the skills and knowledge needed to excel in automotive diagnostics without disrupting your work schedule. Our remote support services also provide real-time assistance with complex diagnostic challenges, ensuring you have the support you need when you need it.

6. Common Mistakes to Avoid When Diagnosing Thermoelectric Climate Seats

Diagnosing thermoelectric climate seats can be challenging, and technicians often make common mistakes that can lead to misdiagnosis and unnecessary repairs. Here are some mistakes to avoid:

6.1 Neglecting DTC Analysis

Failing to properly research and understand the DTCs can lead to incorrect assumptions about the problem. Always consult the vehicle’s service manual or OEM diagnostic tool for detailed information about each code.

6.2 Ignoring Live Data

Relying solely on DTCs without monitoring live data can result in overlooking critical information about the system’s performance. Live data can reveal subtle anomalies that may not trigger a DTC.

6.3 Skipping Actuator Tests

Failing to perform actuator tests can lead to misdiagnosing faulty components. Actuator tests provide a direct way to verify the functionality of individual components.

6.4 Overlooking Basic Checks

Before diving into advanced diagnostics, always perform basic checks, such as inspecting wiring, connectors, and fuses. Simple issues like a loose connection or blown fuse can often be the cause of the problem.

6.5 Failing to Verify Repairs

After making repairs, always clear the DTCs and retest the system to ensure the issue has been resolved. This step is crucial to prevent comebacks and ensure customer satisfaction.

7. Future Trends in Thermoelectric Climate Seat Diagnostics

As automotive technology continues to evolve, so too will the diagnostic techniques and tools used to service thermoelectric climate seats. Some future trends to watch for include:

7.1 Enhanced Diagnostic Capabilities

OEM tools will likely offer even more advanced diagnostic capabilities, such as:

- Predictive diagnostics: Using data analytics to predict potential issues before they occur.

- Remote diagnostics: Allowing technicians to diagnose vehicles remotely using telematics data.

- Artificial intelligence (AI): Using AI to analyze diagnostic data and provide technicians with more accurate and efficient troubleshooting guidance.

7.2 Integration with Cloud-Based Platforms

Diagnostic tools will increasingly integrate with cloud-based platforms, providing technicians with access to:

- Real-time data updates.

- Technical service bulletins (TSBs).

- Wiring diagrams.

- Diagnostic procedures.

- Collaboration tools.

7.3 Augmented Reality (AR) Applications

AR technology may be used to overlay diagnostic information onto the vehicle, providing technicians with a more intuitive and efficient way to troubleshoot issues.

8. Key Takeaways for Effective Climate Seat Diagnostics

- Thermoelectric climate seats require specialized diagnostic tools and techniques.

- OEM diagnostic tools offer unparalleled access to the SCME and other critical components.

- Proper training is essential for effectively using OEM tools and diagnosing complex issues.

- Avoid common mistakes by following a systematic diagnostic approach and performing thorough inspections.

- Stay up-to-date with the latest trends in automotive diagnostics to remain competitive in the industry.

9. How CAR-SCAN-TOOL.EDU.VN Prepares Technicians for the Future of Automotive Diagnostics

CAR-SCAN-TOOL.EDU.VN is committed to providing technicians with the training and resources they need to succeed in the rapidly evolving automotive industry. Our programs cover the latest diagnostic technologies and techniques, including:

- OEM diagnostic tools.

- Advanced data analysis.

- Electrical system troubleshooting.

- Climate control diagnostics.

- Remote diagnostics.

By investing in training with CAR-SCAN-TOOL.EDU.VN, technicians can gain a competitive edge and position themselves for long-term success.

10. Frequently Asked Questions (FAQs) About Thermoelectric Climate Seat Diagnostics

10.1 What is a thermoelectric climate seat?

A thermoelectric climate seat is an advanced automotive seat that uses a thermoelectric device (TED) to both heat and cool the seat, providing enhanced comfort in various weather conditions.

10.2 Why do thermoelectric climate seats require specialized diagnostic tools?

These systems are more complex than traditional heated seats, involving multiple sensors, blower motors, and a dedicated control module (SCME). Standard OBD-II scanners often lack the ability to access the specific data and perform the necessary tests to diagnose issues within the system.

10.3 What are the key components of a thermoelectric climate seat system?

The key components include blower motors, a thermoelectric device (TED), temperature sensors, the seat climate control module (SCME), and a control interface.

10.4 What is the SCME and what does it do?

The SCME (Seat Climate Control Module) controls the heating and cooling functions of the seats based on user settings and sensor data.

10.5 What types of diagnostic trouble codes (DTCs) are common in thermoelectric climate seat systems?

Common DTCs include overtemperature faults (B2729/B2730), temperature difference faults between the seat cushion and backrest (B272A/B272B), communication errors, and component failure codes.

10.6 How can live data monitoring help diagnose climate seat issues?

Live data monitoring allows technicians to observe the system’s performance in real-time. It provides crucial data points such as seat cushion temperature, backrest temperature, blower motor speed, and TED voltage/current, helping identify anomalies that may indicate a problem.

10.7 What are actuator tests and how are they used in climate seat diagnostics?

Actuator tests enable technicians to directly control individual components of the thermoelectric climate seat system, such as blower motors and the TED. This feature helps verify the functionality of each component.

10.8 Can the SCME be recalibrated or reprogrammed?

Yes, in some cases, issues with thermoelectric climate seats can be resolved through recalibration or reprogramming of the SCME. OEM tools provide the necessary software and procedures to perform these tasks.

10.9 What are some common mistakes to avoid when diagnosing thermoelectric climate seats?

Common mistakes include neglecting DTC analysis, ignoring live data, skipping actuator tests, overlooking basic checks, and failing to verify repairs.

10.10 How can CAR-SCAN-TOOL.EDU.VN help technicians improve their climate seat diagnostic skills?

CAR-SCAN-TOOL.EDU.VN offers comprehensive training programs designed to equip technicians with the skills and knowledge needed to effectively use OEM diagnostic tools and diagnose complex automotive systems, including thermoelectric climate seats. Our courses cover everything from basic principles to advanced troubleshooting techniques.

11. Conclusion: Mastering Thermoelectric Climate Seat Diagnostics with the Right Tools and Training

Diagnosing thermoelectric climate seat issues requires a combination of specialized tools, technical knowledge, and practical experience. OEM diagnostic tools provide the necessary access to vehicle systems and components, while comprehensive training programs from institutions like CAR-SCAN-TOOL.EDU.VN equip technicians with the skills to effectively use these tools and diagnose complex issues. By investing in the right tools and training, technicians can enhance their diagnostic capabilities, improve customer satisfaction, and stay ahead in the rapidly evolving automotive industry.

Ready to take your automotive diagnostic skills to the next level? Contact CAR-SCAN-TOOL.EDU.VN today to learn more about our comprehensive training programs and unlock your potential as a skilled automotive technician. Our expert-led courses, hands-on training, and flexible learning options will empower you to master the latest diagnostic technologies and excel in your career.

Don’t let complex diagnostic challenges hold you back. Join the CAR-SCAN-TOOL.EDU.VN community and gain the knowledge and skills you need to succeed. Contact us now to get started.

Address: 555 Automotive Way, Suite 100, Los Angeles, CA 90017, United States

WhatsApp: +1 (641) 206-8880

Website: CAR-SCAN-TOOL.EDU.VN

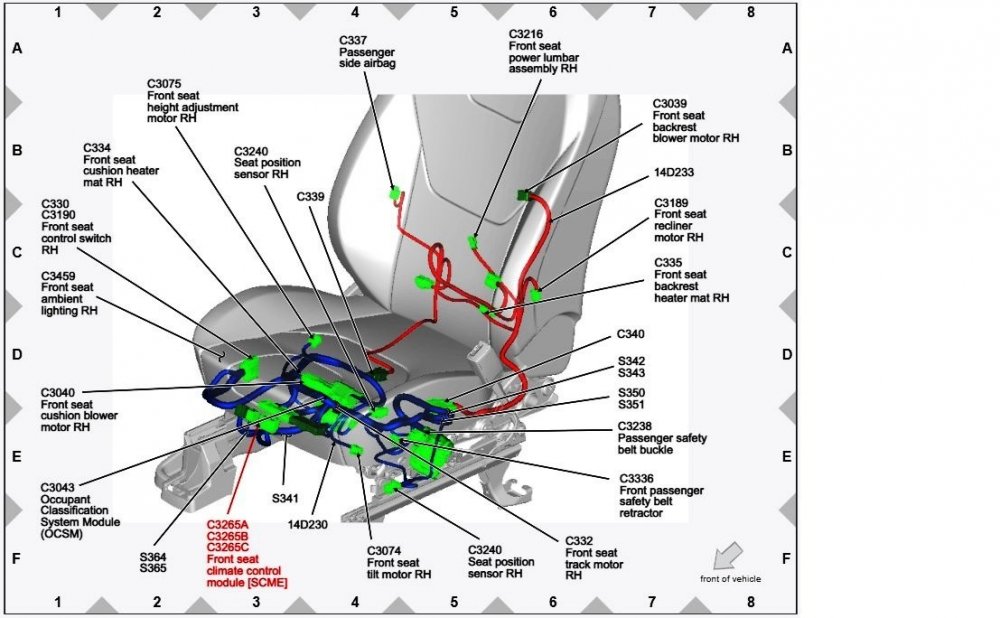

SCME Location Beneath Passenger Seat

SCME Location Beneath Passenger Seat