Are you looking to understand if Original Equipment Manufacturer (OEM) diagnostic tools can test actuators controlling compression ratio changes? Absolutely! OEM diagnostic tools are specifically designed to interact with and test various components, including actuators controlling compression ratio changes. At CAR-SCAN-TOOL.EDU.VN, we emphasize the importance of comprehensive training to effectively utilize these tools. Mastering these OEM tools through specialized remote technician education and automotive scanner training enhances diagnostic skills and ensures accurate assessments.

Contents

- 1. Understanding Compression Ratio Control Systems

- 2. The Role of Actuators in Compression Ratio Adjustment

- 3. OEM Diagnostic Tools: An Overview

- 4. Functional Testing with OEM Tools

- 5. Can OEM Tools Test Actuators Controlling Compression Ratio Changes?

- 6. Examples of OEM Actuator Tests

- 7. Aftermarket Scan Tools and Actuator Testing

- 8. The Importance of Training on OEM Tools

- 9. Common Issues in Compression Ratio Control Systems

- 10. Diagnosing Actuator Issues with OEM Tools

- 11. Repairing Compression Ratio Control Systems

- 12. The Advantage of OEM Data in Diagnostics

- 13. Remote Technician Education at CAR-SCAN-TOOL.EDU.VN

- 14. Understanding Diagnostic Trouble Codes (DTCs)

- 15. The Future of Automotive Diagnostics

- 16. The Value of Continuous Learning in Automotive Technology

- 17. Integrating OEM Tools into Your Diagnostic Workflow

- 18. Practical Tips for Using OEM Diagnostic Tools

- 19. The Benefits of Bi-Directional Control in Diagnostics

- 20. Actuator Testing Best Practices

- 21. The Impact of Emissions Regulations on Engine Technology

- 22. Choosing the Right Diagnostic Tool for Your Needs

- 23. Real-World Applications of OEM Diagnostic Tools

- 24. Enhancing Customer Satisfaction Through Accurate Diagnostics

- 25. Key Takeaways for Automotive Technicians

- 26. How to Stay Updated with the Latest OEM Tool Updates

- 27. The Importance of Proper Wiring and Connections in Actuator Testing

- 28. Understanding the Relationship Between Sensors and Actuators

- 29. How to Use Live Data Effectively During Diagnostics

- 30. The Role of the Engine Control Unit (ECU) in Compression Ratio Control

- FAQ: OEM Tools and Compression Ratio Control Systems

- 1. What are the main benefits of using OEM diagnostic tools?

- 2. How can I learn to use OEM diagnostic tools effectively?

- 3. Are aftermarket scan tools suitable for testing compression ratio control actuators?

- 4. What are the common problems in compression ratio control systems?

- 5. Why is access to OEM data essential for accurate diagnostics?

- 6. What steps are involved in repairing compression ratio control systems?

- 7. How can I stay up-to-date with the latest automotive diagnostic technologies?

- 8. What is bi-directional control, and why is it important?

- 9. How do emissions regulations impact the development of engine technology?

- 10. How can I integrate OEM tools into my existing diagnostic workflow?

1. Understanding Compression Ratio Control Systems

What are compression ratio control systems and why are they important? Compression ratio control systems are advanced automotive technologies that dynamically adjust the compression ratio of an engine to optimize performance and efficiency. This adjustment is typically achieved using actuators that modify the mechanical characteristics of the engine, such as altering the connecting rod length or adjusting the piston stroke. These systems are essential for modern engines to meet stringent emissions standards and deliver improved fuel economy without sacrificing power.

- Enhanced Efficiency: Variable compression ratios allow engines to operate efficiently under a wider range of conditions.

- Reduced Emissions: Optimizing combustion reduces harmful emissions, helping vehicles meet environmental regulations.

- Improved Performance: Adjusting the compression ratio can enhance engine power and responsiveness.

2. The Role of Actuators in Compression Ratio Adjustment

What is the role of actuators in compression ratio adjustment? Actuators are critical components that execute the adjustments necessary for changing the compression ratio. These actuators can be electromechanical, hydraulic, or pneumatic devices controlled by the engine control unit (ECU). They receive signals from the ECU based on various sensor inputs, such as engine load, speed, and temperature, to modify the engine’s mechanical configuration.

- Electromechanical Actuators: These use electric motors and gears to precisely adjust engine components.

- Hydraulic Actuators: Employ hydraulic pressure to move and position parts within the engine.

- Pneumatic Actuators: Utilize compressed air to effect changes in the engine’s geometry.

3. OEM Diagnostic Tools: An Overview

What are OEM diagnostic tools and how do they differ from aftermarket tools? OEM (Original Equipment Manufacturer) diagnostic tools are specialized devices developed by car manufacturers to diagnose and service their vehicles. These tools provide in-depth access to vehicle systems, allowing technicians to perform comprehensive diagnostics, programming, and functional tests. Unlike aftermarket tools, OEM tools are tailored specifically to the manufacturer’s vehicles, ensuring compatibility and accuracy.

- Comprehensive Access: OEM tools offer complete access to all vehicle systems, including proprietary data and control functions.

- Accurate Diagnostics: Designed with manufacturer-specific data, OEM tools provide the most accurate diagnostic information.

- Programming Capabilities: OEM tools can perform advanced programming and calibration functions, essential for modern vehicle maintenance.

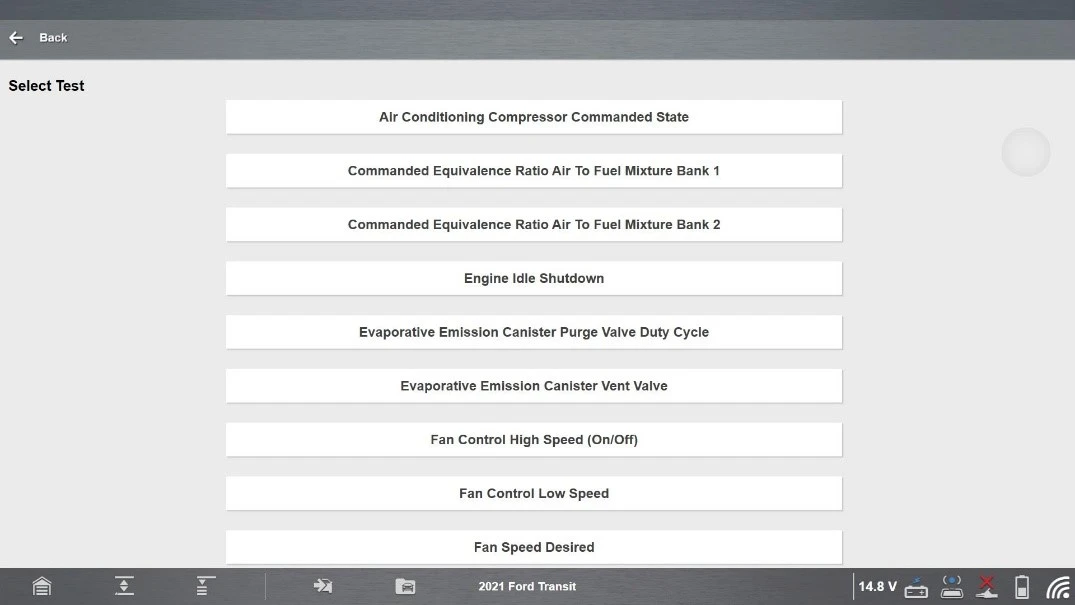

4. Functional Testing with OEM Tools

How can functional testing with OEM tools help diagnose compression ratio control systems? Functional testing with OEM tools allows technicians to directly interact with the engine’s control systems, including the actuators that manage compression ratio changes. These tests can activate actuators, monitor their responses, and verify their performance against specified parameters. Functional tests are crucial for identifying faults in the actuator system, such as mechanical failures, electrical issues, or control system problems.

- Actuator Activation: OEM tools can command actuators to move and adjust, allowing technicians to observe their operation.

- Real-Time Monitoring: The tools monitor sensor data and actuator responses in real-time, providing immediate feedback on system performance.

- Diagnostic Codes: OEM tools can read and interpret diagnostic trouble codes (DTCs) related to the compression ratio control system, aiding in pinpointing issues.

5. Can OEM Tools Test Actuators Controlling Compression Ratio Changes?

Can OEM diagnostic tools specifically test actuators controlling compression ratio changes? Yes, OEM diagnostic tools are designed to test actuators controlling compression ratio changes. These tools can perform specific tests to verify the functionality of the actuators, ensuring they are responding correctly to commands from the engine control unit (ECU). The tests typically involve activating the actuators and monitoring their performance through sensor feedback.

- Detailed Diagnostics: OEM tools offer in-depth diagnostic capabilities tailored to specific engine designs.

- Actuator-Specific Tests: Technicians can perform tests specifically designed for compression ratio control actuators.

- Data Interpretation: OEM tools provide detailed data and guidance for interpreting test results, helping technicians identify faults.

6. Examples of OEM Actuator Tests

What are some examples of OEM actuator tests for compression ratio control systems? Several OEM actuator tests can be performed to diagnose compression ratio control systems. These tests vary depending on the vehicle manufacturer and engine design, but they generally involve activating the actuators and monitoring their response through sensor data. Here are a few examples:

- Actuator Position Test: This test verifies that the actuator is moving to the correct position in response to ECU commands.

- Response Time Test: This measures how quickly the actuator responds to changes in the control signal.

- Feedback Signal Test: This checks the accuracy of the feedback signal from the actuator, ensuring the ECU receives correct information about the actuator’s position.

7. Aftermarket Scan Tools and Actuator Testing

Can aftermarket scan tools also test actuators controlling compression ratio changes? While some advanced aftermarket scan tools offer bi-directional control capabilities, their ability to test actuators controlling compression ratio changes may be limited compared to OEM tools. Aftermarket tools often lack the depth of diagnostic functions and specific tests available in OEM tools, potentially hindering accurate diagnosis.

- Limited Functionality: Aftermarket tools may not support all the specialized tests required for advanced systems like compression ratio control.

- Generic Data: The data provided by aftermarket tools may be less detailed and harder to interpret than that from OEM tools.

- Compatibility Issues: Aftermarket tools may not be fully compatible with all vehicle models, leading to inaccurate results.

8. The Importance of Training on OEM Tools

Why is training essential for using OEM diagnostic tools effectively? Training is critical for effectively using OEM diagnostic tools, especially when dealing with complex systems like compression ratio control. Proper training ensures that technicians understand the tool’s functions, can interpret diagnostic data accurately, and can perform functional tests correctly. At CAR-SCAN-TOOL.EDU.VN, we offer specialized training programs to equip technicians with the skills needed to master OEM tools.

- Tool Proficiency: Training ensures technicians are proficient in using all features of the OEM diagnostic tool.

- Data Interpretation: Technicians learn how to accurately interpret diagnostic data, including sensor readings and fault codes.

- Correct Procedures: Training covers the correct procedures for performing functional tests and other diagnostic tasks.

9. Common Issues in Compression Ratio Control Systems

What are some common issues encountered in compression ratio control systems? Several common issues can arise in compression ratio control systems, affecting their performance and efficiency. These problems can stem from mechanical failures, electrical faults, or issues within the control system. Identifying and addressing these issues promptly is essential for maintaining engine performance and reducing emissions.

- Actuator Failure: Actuators can fail due to wear and tear, electrical faults, or mechanical damage.

- Sensor Malfunctions: Faulty sensors can provide incorrect data to the ECU, leading to improper compression ratio adjustments.

- Wiring Problems: Damaged or corroded wiring can disrupt communication between the ECU and actuators.

10. Diagnosing Actuator Issues with OEM Tools

How can OEM tools help diagnose actuator issues in compression ratio control systems? OEM tools provide a range of diagnostic functions specifically designed to identify actuator issues in compression ratio control systems. These tools can perform functional tests, monitor sensor data, and read diagnostic trouble codes (DTCs) to pinpoint problems within the system. By using OEM tools, technicians can accurately diagnose and address actuator issues, restoring engine performance and efficiency.

- Functional Tests: OEM tools can activate actuators and monitor their response to identify mechanical or electrical faults.

- Sensor Data Analysis: Technicians can use OEM tools to analyze sensor data related to the compression ratio control system, identifying irregularities or inconsistencies.

- DTC Interpretation: OEM tools provide detailed information about diagnostic trouble codes, helping technicians understand the nature and location of the fault.

11. Repairing Compression Ratio Control Systems

What are the steps involved in repairing compression ratio control systems? Repairing compression ratio control systems typically involves several key steps, from initial diagnosis to component replacement and system verification. Proper repair procedures ensure that the system is restored to its optimal condition, delivering improved engine performance and reduced emissions.

- Diagnosis: Use OEM diagnostic tools to identify the root cause of the problem, whether it is an actuator failure, sensor malfunction, or wiring issue.

- Component Replacement: Replace faulty components with new or remanufactured parts, ensuring they meet OEM specifications.

- System Verification: After repairs, use OEM tools to verify that the system is functioning correctly, performing functional tests and monitoring sensor data.

12. The Advantage of OEM Data in Diagnostics

Why is having access to OEM data crucial for accurate diagnostics? Access to OEM (Original Equipment Manufacturer) data is crucial for accurate diagnostics because it provides technicians with the most specific and reliable information about the vehicle’s systems. OEM data includes detailed specifications, diagnostic procedures, and troubleshooting guides developed by the vehicle manufacturer. This ensures that technicians can accurately interpret diagnostic data and perform repairs according to factory standards.

- Specific Information: OEM data provides detailed information specific to the vehicle’s make, model, and year, ensuring accurate diagnostics.

- Reliable Procedures: Technicians can follow OEM-recommended diagnostic and repair procedures, reducing the risk of errors.

- Factory Standards: Repairs performed using OEM data meet factory standards, ensuring optimal performance and reliability.

13. Remote Technician Education at CAR-SCAN-TOOL.EDU.VN

How can remote technician education at CAR-SCAN-TOOL.EDU.VN enhance your diagnostic skills? Remote technician education at CAR-SCAN-TOOL.EDU.VN offers comprehensive training programs designed to enhance your diagnostic skills and equip you with the knowledge needed to master OEM diagnostic tools. Our courses cover a range of topics, from basic diagnostics to advanced system troubleshooting, providing you with the skills to tackle complex automotive issues.

- Flexible Learning: Our remote courses allow you to learn at your own pace, fitting your education into your busy schedule.

- Expert Instructors: Our courses are taught by experienced automotive technicians and industry experts, providing you with valuable insights and practical knowledge.

- Hands-On Training: Through virtual labs and simulations, you’ll gain hands-on experience using OEM diagnostic tools and performing functional tests.

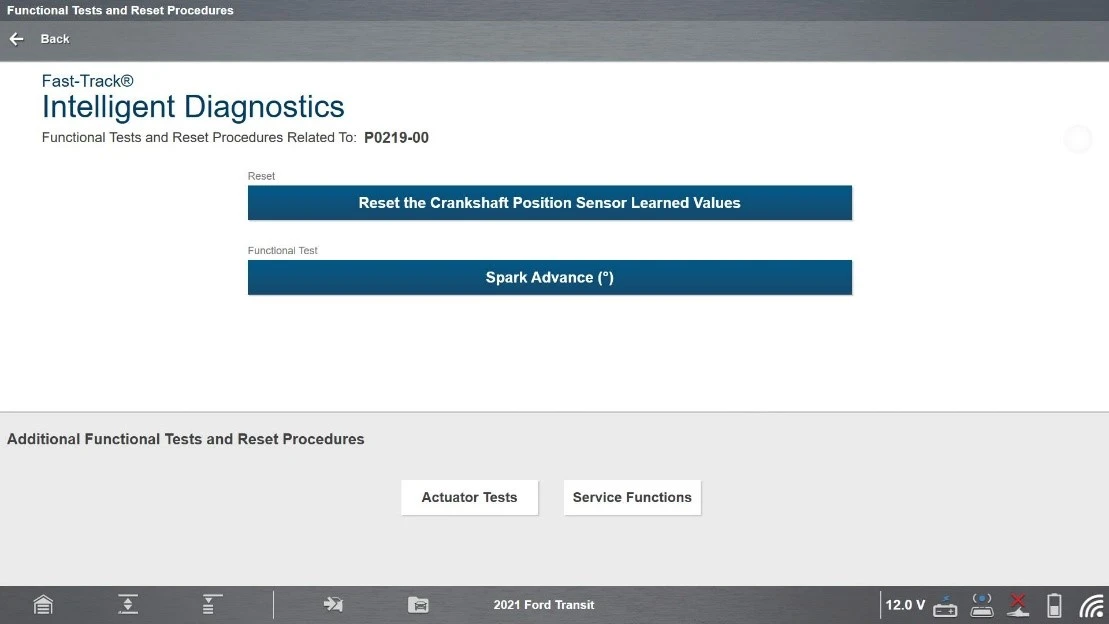

14. Understanding Diagnostic Trouble Codes (DTCs)

How do Diagnostic Trouble Codes (DTCs) assist in diagnosing compression ratio control systems? Diagnostic Trouble Codes (DTCs) are codes generated by the vehicle’s computer system when it detects a malfunction. These codes provide valuable information that can assist in diagnosing issues within compression ratio control systems. DTCs can indicate problems such as actuator failures, sensor malfunctions, or wiring issues, helping technicians quickly identify the source of the problem.

- Quick Identification: DTCs provide a quick way to identify potential issues within the compression ratio control system.

- Specific Information: Each DTC corresponds to a specific type of malfunction, helping technicians pinpoint the problem.

- Troubleshooting Guidance: OEM diagnostic tools provide detailed information about each DTC, including possible causes and recommended troubleshooting steps.

15. The Future of Automotive Diagnostics

What are the future trends in automotive diagnostics and how can technicians prepare for them? The field of automotive diagnostics is constantly evolving, with new technologies and techniques emerging to address the increasing complexity of modern vehicles. Some of the key future trends include increased reliance on data analytics, artificial intelligence, and remote diagnostics. Technicians can prepare for these trends by investing in ongoing training and staying up-to-date with the latest advancements in diagnostic technology.

- Data Analytics: Advanced diagnostic systems will use data analytics to identify patterns and predict potential issues before they occur.

- Artificial Intelligence: AI-powered diagnostic tools will assist technicians in troubleshooting complex problems and making informed repair decisions.

- Remote Diagnostics: Remote diagnostic services will allow technicians to diagnose and repair vehicles from a distance, improving efficiency and reducing downtime.

16. The Value of Continuous Learning in Automotive Technology

Why is continuous learning essential for automotive technicians? Continuous learning is essential for automotive technicians because the automotive industry is constantly evolving. New technologies, systems, and diagnostic techniques are introduced regularly, requiring technicians to stay up-to-date to effectively diagnose and repair modern vehicles. Continuous learning helps technicians maintain their skills, improve their knowledge, and provide high-quality service to their customers.

- Staying Current: Continuous learning ensures that technicians stay current with the latest advancements in automotive technology.

- Improved Skills: Ongoing training helps technicians improve their diagnostic and repair skills, enhancing their ability to solve complex problems.

- Career Advancement: Technicians who invest in continuous learning are more likely to advance in their careers and earn higher salaries.

17. Integrating OEM Tools into Your Diagnostic Workflow

How can you seamlessly integrate OEM tools into your existing diagnostic workflow? Integrating OEM tools into your diagnostic workflow can significantly improve the accuracy and efficiency of your diagnostic process. To do this effectively, start by familiarizing yourself with the tool’s functions and capabilities. Then, develop a systematic approach to using the tool, incorporating it into your standard diagnostic procedures.

- Familiarization: Take the time to learn the features and functions of the OEM tool.

- Systematic Approach: Develop a consistent process for using the tool in your diagnostic routine.

- Training: Ensure that all technicians receive adequate training on the tool’s operation and maintenance.

18. Practical Tips for Using OEM Diagnostic Tools

What are some practical tips for using OEM diagnostic tools effectively? To maximize the benefits of using OEM diagnostic tools, consider the following practical tips:

- Keep the Tool Updated: Regularly update the tool’s software to ensure you have the latest diagnostic data and functions.

- Follow OEM Procedures: Adhere to the OEM-recommended diagnostic and repair procedures to ensure accuracy and reliability.

- Document Your Work: Keep detailed records of your diagnostic findings and repairs, which can be valuable for future reference.

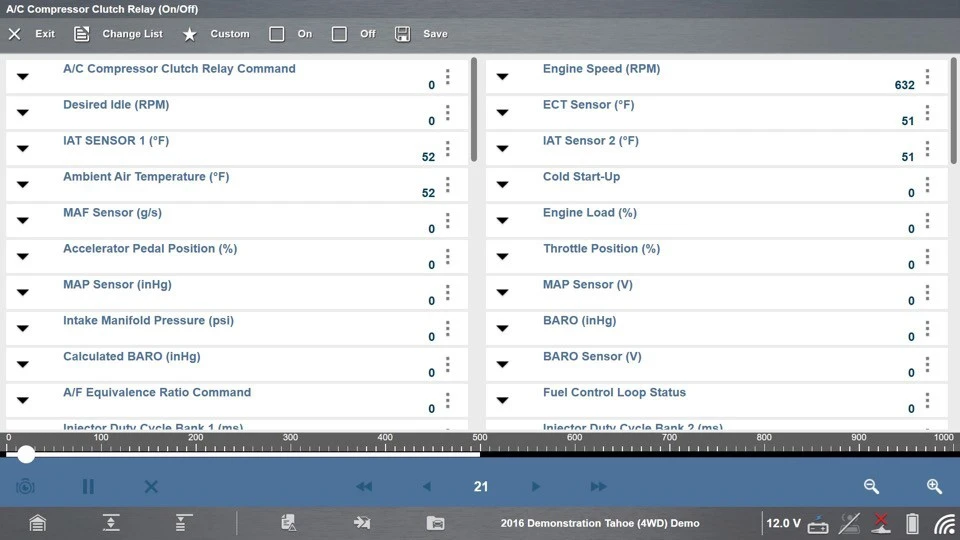

19. The Benefits of Bi-Directional Control in Diagnostics

What are the benefits of bi-directional control in automotive diagnostics? Bi-directional control is a powerful diagnostic capability that allows technicians to interact directly with the vehicle’s computer systems. This functionality enables technicians to activate components, monitor sensor data, and perform functional tests, providing valuable insights into system performance. The benefits of bi-directional control include:

- Enhanced Diagnostics: Bi-directional control allows technicians to perform comprehensive diagnostics, identifying issues that may not be apparent through traditional methods.

- Efficient Troubleshooting: By activating components and monitoring their response, technicians can quickly pinpoint the source of the problem.

- Verification of Repairs: Bi-directional control can be used to verify that repairs have been performed correctly, ensuring that the system is functioning as intended.

20. Actuator Testing Best Practices

What are the best practices for testing actuators in automotive systems? Testing actuators effectively requires a systematic approach and attention to detail. Here are some best practices to follow:

- Use OEM Tools: Whenever possible, use OEM diagnostic tools to ensure access to the most specific and accurate diagnostic functions.

- Follow Test Procedures: Adhere to the OEM-recommended test procedures for each actuator, ensuring that you perform the tests correctly.

- Monitor Sensor Data: Pay close attention to sensor data during actuator testing, looking for irregularities or inconsistencies that may indicate a problem.

21. The Impact of Emissions Regulations on Engine Technology

How have emissions regulations influenced the development of engine technology? Emissions regulations have had a profound impact on the development of engine technology, driving manufacturers to innovate and develop new systems to reduce harmful emissions. Technologies such as variable compression ratio control, direct fuel injection, and exhaust gas recirculation have all been developed in response to increasingly stringent emissions standards.

- Innovation: Emissions regulations have spurred innovation in engine technology, leading to more efficient and environmentally friendly vehicles.

- Advanced Systems: Modern engines incorporate a range of advanced systems designed to reduce emissions, such as catalytic converters and particulate filters.

- Improved Efficiency: Efforts to reduce emissions have also led to improvements in fuel efficiency, benefiting consumers and the environment.

22. Choosing the Right Diagnostic Tool for Your Needs

How do you select the right diagnostic tool for your specific needs? Selecting the right diagnostic tool depends on your specific needs and the types of vehicles you work on. Consider the following factors when choosing a diagnostic tool:

- Vehicle Coverage: Ensure that the tool supports the makes and models of vehicles you service.

- Diagnostic Functions: Look for a tool that offers a comprehensive range of diagnostic functions, including bi-directional control and functional testing.

- Ease of Use: Choose a tool that is easy to use and has a user-friendly interface.

23. Real-World Applications of OEM Diagnostic Tools

What are some real-world applications of OEM diagnostic tools in automotive repair? OEM diagnostic tools are used in a wide range of automotive repair scenarios, from routine maintenance to complex system troubleshooting. Here are some examples:

- Engine Diagnostics: OEM tools are used to diagnose engine problems such as misfires, poor performance, and emissions issues.

- Transmission Repairs: OEM tools can diagnose transmission problems and perform necessary calibrations and adjustments.

- Electrical System Troubleshooting: OEM tools are used to troubleshoot electrical system problems, such as faulty sensors, wiring issues, and computer malfunctions.

24. Enhancing Customer Satisfaction Through Accurate Diagnostics

How can accurate diagnostics improve customer satisfaction in automotive repair? Accurate diagnostics play a crucial role in enhancing customer satisfaction by ensuring that repairs are performed correctly the first time. By using OEM diagnostic tools and following OEM procedures, technicians can accurately identify the root cause of the problem, reducing the risk of misdiagnosis and repeat repairs.

- First-Time Fixes: Accurate diagnostics increase the likelihood of performing a first-time fix, saving customers time and money.

- Reduced Downtime: By quickly and accurately diagnosing problems, technicians can minimize vehicle downtime, getting customers back on the road sooner.

- Trust and Confidence: Customers who receive accurate and reliable service are more likely to trust and have confidence in the repair shop.

25. Key Takeaways for Automotive Technicians

What are the key takeaways for automotive technicians regarding compression ratio control systems and OEM tools? For automotive technicians working with compression ratio control systems and OEM tools, here are some key takeaways:

- Understand the Technology: Familiarize yourself with the principles and operation of compression ratio control systems.

- Master OEM Tools: Invest time in learning how to use OEM diagnostic tools effectively.

- Stay Updated: Keep abreast of the latest advancements in automotive technology and diagnostic techniques.

26. How to Stay Updated with the Latest OEM Tool Updates

What is the best way to keep your OEM diagnostic tools updated with the latest software? Keeping your OEM diagnostic tools updated with the latest software is essential for accurate diagnostics and effective repairs. Here’s how you can stay updated:

- Regularly Check for Updates: Visit the OEM’s website or software platform to check for available updates.

- Enable Automatic Updates: If your tool supports it, enable automatic updates to ensure you always have the latest software.

- Follow OEM Communications: Subscribe to OEM newsletters or follow their social media channels to receive notifications about new updates.

27. The Importance of Proper Wiring and Connections in Actuator Testing

Why is it crucial to ensure proper wiring and connections when testing actuators? Proper wiring and connections are crucial when testing actuators because faulty connections can lead to inaccurate test results or even damage the actuator or diagnostic tool. Always ensure that all connections are secure and that the wiring is in good condition before performing any tests.

- Accurate Results: Secure connections ensure that the test signals are transmitted correctly, providing accurate results.

- Prevent Damage: Proper wiring prevents electrical shorts or overloads that could damage the actuator or diagnostic tool.

- Safe Testing: Ensuring proper wiring and connections promotes safe testing practices, protecting you and the equipment.

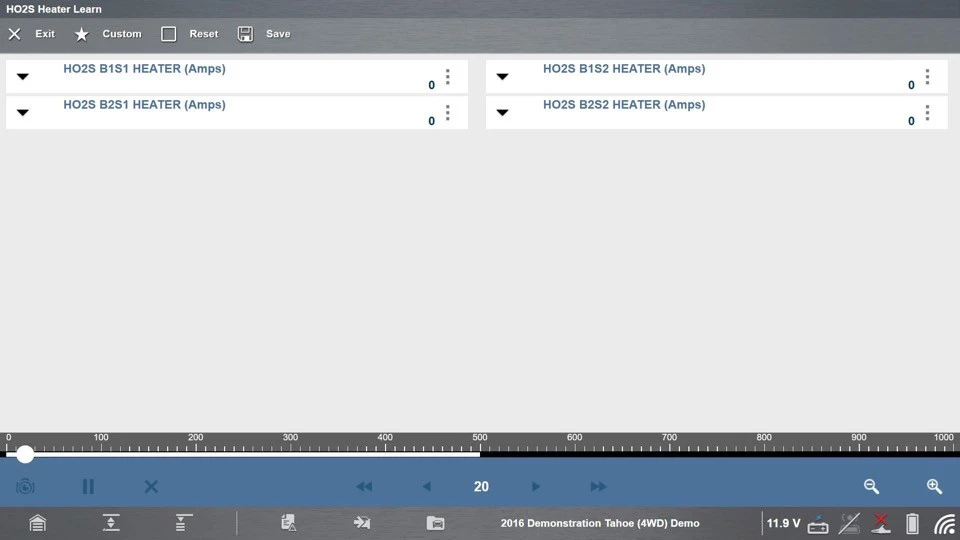

28. Understanding the Relationship Between Sensors and Actuators

How do sensors and actuators work together in compression ratio control systems? Sensors and actuators work in tandem within compression ratio control systems to ensure optimal engine performance. Sensors provide data about various engine parameters, such as load, speed, and temperature. This data is used by the engine control unit (ECU) to determine the appropriate compression ratio. The ECU then sends signals to the actuators, which adjust the engine’s mechanical configuration to achieve the desired compression ratio.

- Data Input: Sensors provide real-time data about engine conditions.

- Control Signals: The ECU uses this data to generate control signals for the actuators.

- Precise Adjustments: Actuators respond to these signals, making precise adjustments to the engine’s compression ratio.

29. How to Use Live Data Effectively During Diagnostics

What are some tips for using live data effectively when diagnosing compression ratio control systems? Using live data effectively can significantly enhance your diagnostic capabilities. Here are some tips for using live data when diagnosing compression ratio control systems:

- Monitor Relevant Parameters: Focus on monitoring parameters that are directly related to the compression ratio control system, such as actuator position, sensor readings, and ECU commands.

- Compare to Specifications: Compare the live data readings to the OEM-specified values to identify any deviations or irregularities.

- Look for Patterns: Analyze the live data over time, looking for patterns or trends that may indicate a problem.

30. The Role of the Engine Control Unit (ECU) in Compression Ratio Control

What role does the Engine Control Unit (ECU) play in managing compression ratio control systems? The Engine Control Unit (ECU) is the brain of the compression ratio control system, responsible for receiving data from various sensors, processing that data, and sending control signals to the actuators. The ECU continuously monitors engine conditions and adjusts the compression ratio to optimize performance, efficiency, and emissions.

- Data Processing: The ECU processes data from sensors to determine the appropriate compression ratio.

- Control Signals: The ECU sends control signals to the actuators, directing them to adjust the engine’s mechanical configuration.

- Closed-Loop Control: The ECU uses feedback from sensors to fine-tune the compression ratio, ensuring optimal performance under all conditions.

At CAR-SCAN-TOOL.EDU.VN, we are dedicated to providing top-tier remote technician education and automotive scanner training. Our goal is to empower you with the skills and knowledge necessary to excel in the rapidly evolving field of automotive diagnostics. Contact us today via Whatsapp at +1 (641) 206-8880 or visit our website at CAR-SCAN-TOOL.EDU.VN to learn more about our comprehensive training programs and how they can transform your career. Our support office in the USA is located at 555 Automotive Way, Suite 100, Los Angeles, CA 90017, United States.

OEM Diagnostic Tool Testing Actuators

OEM Diagnostic Tool Testing Actuators

Snap-on Security Link Access

Snap-on Security Link Access

A/C Compressor Clutch Functional Test

A/C Compressor Clutch Functional Test

PCM Reset Functional Test

PCM Reset Functional Test

Latest Snap-on Software for Diagnostic Tool

Latest Snap-on Software for Diagnostic Tool

FAQ: OEM Tools and Compression Ratio Control Systems

1. What are the main benefits of using OEM diagnostic tools?

OEM diagnostic tools offer comprehensive access to vehicle systems, accurate diagnostics, and programming capabilities tailored specifically to the manufacturer’s vehicles. This ensures compatibility and accuracy, especially for advanced systems like compression ratio control.

2. How can I learn to use OEM diagnostic tools effectively?

Enroll in a remote technician education program like the one offered at CAR-SCAN-TOOL.EDU.VN. These programs provide comprehensive training, hands-on experience, and expert instruction to master OEM tools.

3. Are aftermarket scan tools suitable for testing compression ratio control actuators?

While some advanced aftermarket scan tools offer bi-directional control, they may lack the depth and specificity of OEM tools. OEM tools are designed with manufacturer-specific data, ensuring accurate diagnostics.

4. What are the common problems in compression ratio control systems?

Common issues include actuator failures, sensor malfunctions, and wiring problems. Regular diagnostics and maintenance can help prevent these issues and maintain optimal engine performance.

5. Why is access to OEM data essential for accurate diagnostics?

OEM data provides detailed specifications, diagnostic procedures, and troubleshooting guides developed by the vehicle manufacturer. This ensures that technicians can accurately interpret diagnostic data and perform repairs according to factory standards.

6. What steps are involved in repairing compression ratio control systems?

Repairing these systems includes diagnosing the issue with OEM tools, replacing faulty components with OEM-specified parts, and verifying the system’s functionality after repairs.

7. How can I stay up-to-date with the latest automotive diagnostic technologies?

Continuous learning is crucial. Participate in remote technician education, attend industry workshops, and subscribe to automotive technology publications to stay informed about the latest advancements.

8. What is bi-directional control, and why is it important?

Bi-directional control allows technicians to interact directly with the vehicle’s computer systems, activating components, monitoring sensor data, and performing functional tests. This capability is essential for comprehensive diagnostics and efficient troubleshooting.

9. How do emissions regulations impact the development of engine technology?

Emissions regulations drive manufacturers to innovate and develop new systems to reduce harmful emissions. Technologies like variable compression ratio control, direct fuel injection, and exhaust gas recirculation have emerged in response to these regulations.

10. How can I integrate OEM tools into my existing diagnostic workflow?

Familiarize yourself with the OEM tool’s functions, develop a systematic approach to using it, and ensure all technicians receive proper training on its operation and maintenance. This seamless integration enhances diagnostic accuracy and efficiency.

Ready to elevate your diagnostic skills and become an expert in using OEM diagnostic tools? Contact CAR-SCAN-TOOL.EDU.VN today via Whatsapp at +1 (641) 206-8880 or visit our website at CAR-SCAN-TOOL.EDU.VN to learn more about our comprehensive training programs. Our support office in the USA is located at 555 Automotive Way, Suite 100, Los Angeles, CA 90017, United States. Unlock your potential with our specialized remote technician education and automotive scanner training!